Main Menu

The Rotor Ground Detection System Model AT-8600 provides

continuous wireless detection of insulation faults on the field windings of brushless generators and motors, combining advanced ground fault measurement techniques with the latest innovations in digital telemetry.

The Rotor Ground Detection System Model AT-8600 provides

continuous wireless detection of insulation faults on the field windings of brushless generators and motors, combining advanced ground fault measurement techniques with the latest innovations in digital telemetry.

The Rotor Ground Detection System Model AT-8600 provides reliable, continuous, wireless detection of insulation faults on the field windings of brushless generators and motors. Advanced ground fault measurement techniques combined with the latest innovations in digital telemetry detect field ground faults before a catastrophic failure occurs, reducing the risk of unscheduled outages and allowing predictive maintenance procedures to be performed. Undetected field ground faults can result in severe damage to rotor insulation and forgings. Such faults can lead to costly rotor repairs and prolonged forced outages. The Rotor Ground Detection System provides operators with a valuable tool for early detection of these faults. Maintenance can be performed at scheduled outages, allowing implementation of a back-up plan prior to shutdown.

The system connects to the field negative terminal and the shaft ground to measure the insulation resistance of the field winding. Unlike other ground detectors, the alarm threshold always represents a fixed level of fault severity and does not change with fault location or excitation voltage. LED diagnostic indicators and self-test capabilities enhance operator confidence in the proper functioning of the system. The Rotor Ground Detection System Model AT-8600 gives operators of generators or synchronous motors with brushless exciters peace of mind and the assurance that a ground fault is not causing hidden damage that could lead to an unexpected and costly long-term outage.

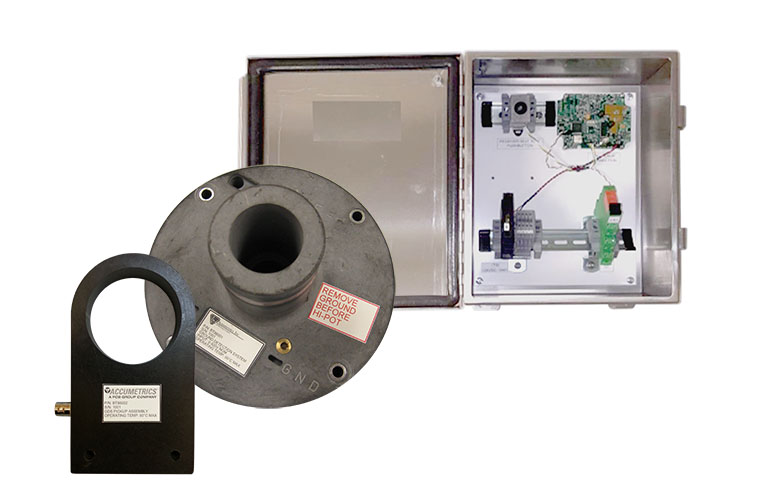

Pickup coil

Rotor-mounted transmitter

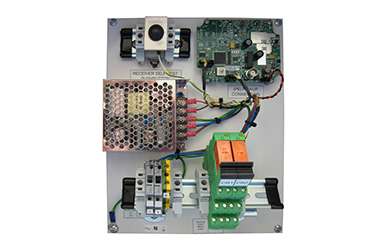

Receiver in NEMA 4 enclosure

| SPECIFICATIONS | |

|---|---|

| Performance | |

| Rotor Connections | Field Negative Terminal |

| Rotor Earth/Ground | |

| Field Voltage | |

| Measurement Range | 0 to 750 VDC |

| Maximum Transient without Damage | 1500 V for 5 seconds |

| Receiver Output Indicators | |

| Alarms | Ground Fault and optional System Malfunction, 2–Form C relay 6 A / 250 VAC contacts |

| LEDs | LED Indicators to aid in identifying a ground fault, malfunction, or self-diagnostic status |

| Power | 100–200 VAC, 50/60 Hz, or 24 VDC |

| Receiver Alarm Outputs | |

| Ground Detection | Alarms when insulation resistance falls below 10k ohm (± 10%) User-adjustable alarm delay from 5 seconds to 22 seconds |

| Malfunction | Alarms when there is a loss of power, failure of receiver, loss of data, open wire detection |

| Alarm Interfaces | Form C relay 6 A / 250 VAC |

| Environment | |

| Ambient Temperature | -40 °F to 194 °F (-40 °C to 90 °C) at Transmitter Module/Pickup Assembly -40 °F to 140 °F (-40 °C to 60 °C) at Receiver Unit |

| Axial Travel | ± 0.25 in (± 6.5 mm) from nominal operating position |

| Rotor Speed | 0 to 3600 RPM nominal; 4320 RPM Max |