Accumetrics’ Induction-powered Telemetry Systems enable wireless measurement of rotating shafts without slip rings, offering solutions from single-channel to custom designs for industries like Marine, Aerospace, Defense, and Power Generation. With

durable split-clamp collars, these telemetry systems allow machine designers and maintenance personnel to measure exactly what is happening on rotating components of a wide range of equipment while it is in operation, even at high RPM.

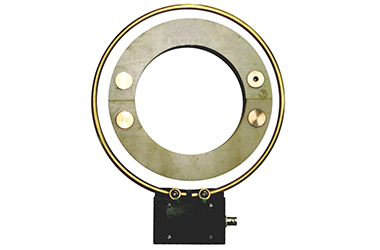

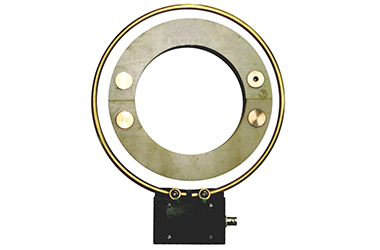

Fully Customizable Induction Powered Telemetry | Model AT-7800

Multi-Channel Telemetry System Model AT-7000 can combine any customized mix of sensors: strain gages, thermocouples, RTDs, or accelerometers – can also measure field voltages, currents, and ground fault currents. The data collected is continuously

streamed to the user as analog ( ±10 V or 4-20 mA) or digital data.

- Real-time shaft measurements transmitted wirelessly without slip rings or batteries

- Custom mix of sensors such as strain gages, RTDs, accelerometers, thermocouples, and more

- Mounting via mid-shaft split clamp-on collars or customized end-of-shaft packages

- Learn more

AccuTemp Rotor Temperature Monitoring | Model AT-7800

- Real-time rotor temperature readings transmitted wirelessly without slip rings or batteries

- Increased production throughput with improved overtemperature monitoring

- Early detection of motor faults due to temperature overage

- Learn more

Single Channel Induction Powered Measurement Transmission | AT-4400

Ideal for long duration applications where accuracy, resolution, low drift, and low noise levels are critical, Single Channel Telemetry systems allow measurement data directly measured on rotating components to be digitized and transmitted off-shaft using

wireless technology. The receiver outputs high bandwidth analog data.

High EMI immunity (usable near variable frequency drives)

High EMI immunity (usable near variable frequency drives)- Flexible output gain, offset, and filtering

- Measurements on shafts rotating at high speeds (up to 17,000 RPM)

- Rugged split-clamp collars ideal for long-term use

- Stands up to corrosive or dirty environments

- Learn more

Safe, Reliable, Non-Contact Measurements Even at High Rotational Speed

How can Accumetrics solve your measurement challenges?

- Speed | Measurements transmitted from shafts rotating at speeds as high as 17,000 RPM

- Reliability | High data integrity and noise immunity: No interference seen from ignition, variable frequency motors, drills, etc.

- Ruggedness | Stands up to harsh environments

- Safety | Tired of tape? Equipment is securely fastened to the shaft with a split-clamp collar

- Ease of Installation | With split-clamp collars, installation is quick and simple, in some cases taking as little as 5-10 minutes

- Support | Accumetrics' commitment to Total Customer Satisfaction (TCS) ensures you'll get the support you need to solve your measurement challenges

Accumetrics' telemetry systems are ideal for torque, temperature (thermocouple and RTD), accelerometer, and electrical measurements on drive shafts of motor-generators. These solutions serve as a rugged and non-contact alternative to slip rings.

Why Use Telemetry as a Replacement for Slip Rings?

When using slip rings for measurement, there is contact between the shaft and a stator. Using wireless telemetry instead of slip rings means the system is

- More reliable

- Easier to maintain

- Free of the worry and hassle of worn brushes that require replacement

High EMI immunity (usable near variable frequency drives)

High EMI immunity (usable near variable frequency drives)